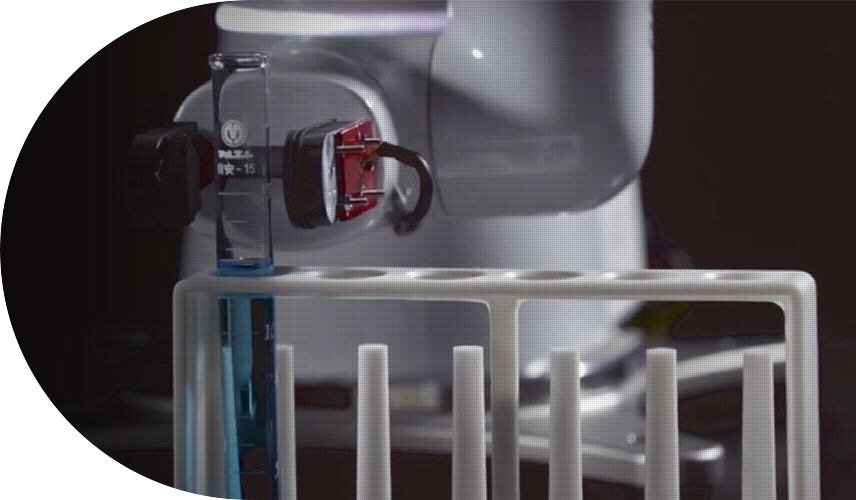

Pre-Touch SensorTK-01N / TK-01G (under development)

By combining infrared rays and our own Edge AI,

Pre-Touch Sensor achieves real-time measurements of “distance and position” of objects at high resolution in a non-contact manner.

The product can measure transparent objects and reflective objects whose measurement is difficult by conventional methods,

and has realized the use of robot hands at various sites where the introduction of robot hands has been given up.

By capturing the distance and position of an object, advancing “holding” by robot handsFeatures of Pre-Touch Sensor

-

01

Now easy handling of objects

that were difficult to handleUsing “Pre-Touch Sensor TK-01 series” equipped with our proprietary infrared mechanism and Edge AI enables measurement of “distance and position” of objects and capture of irregularly shaped objects, soft objects and randomly arranged objects. Although measurement of transparent objects and reflective objects is difficult for conventional optical sensors and cameras, the product can measure such objects, which broaden the possibility of application of robot hands at sites and in areas where the introduction of robot hands has been given up.

-

02

Teaching made simple boosts productivity

In the case of robot hands equipped with “Pre-Touch Sensor TK-01 series”, the robot itself fine-adjusts the position of its own fingertips while measuring objects in real time, so it is operable with “rough teaching.” The product only requires the minimum change of algorithm for each type of work, ensuring reduced burden of setting for System Integrator and operation for engineers at work sites. Time for change of set-up can be shortened, which contributes to “productivity improvement” and “reduction in production cost” at lines for various types of products.

Pre-Touch Sensor Mechanism

-

01

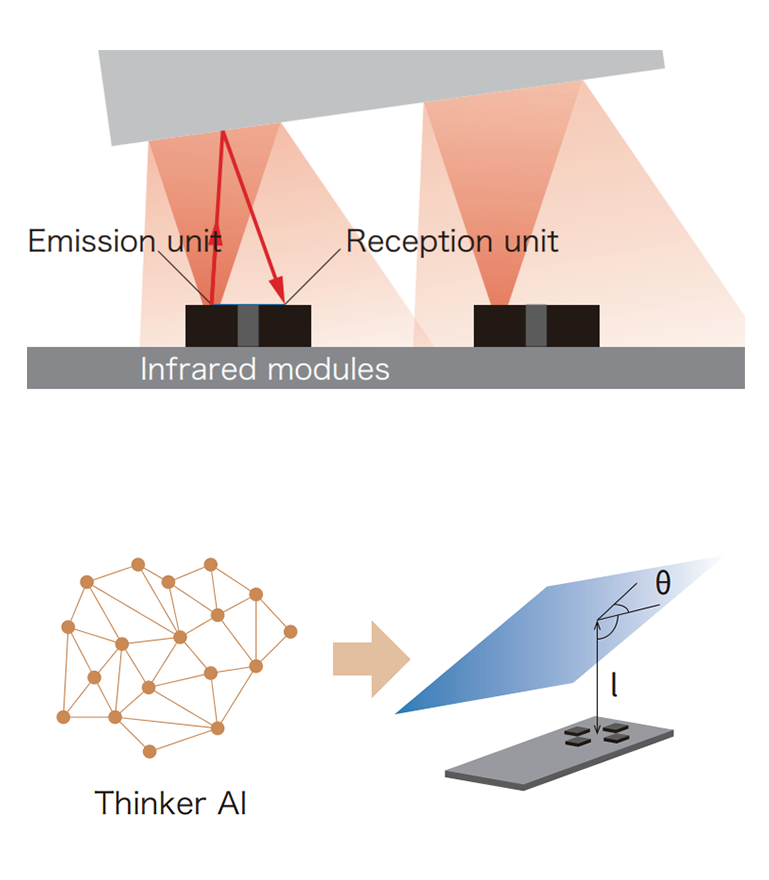

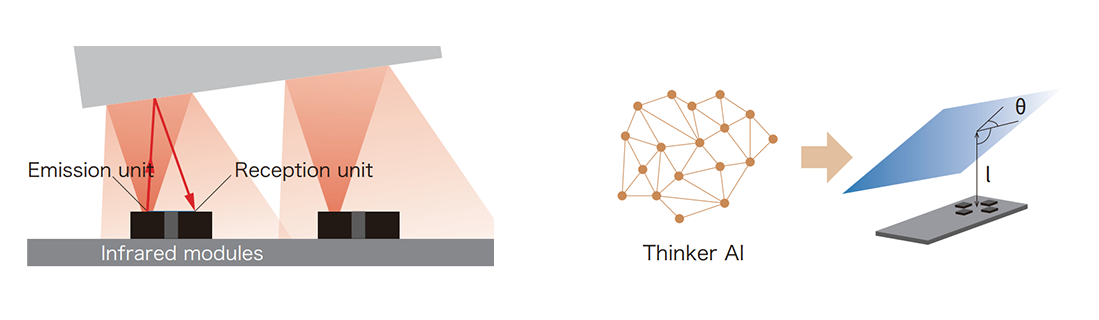

Diffused emission and reception of infrared light

Four infrared modules measure the amount of reflected light corresponding to the distance and angle of the object.

-

02

Lightweight AI model to estimate distances and angles

Lightweight AI model, “Thinker AI” processes the reflected light levels, which differ across materials, to determine distances and angles.

Product Specifications

-

Measured Data

Distance, pitch and Yaw angle

-

Detection Range

1.5 ~ 20.0 mm (RES: 0.1 mm)

-

Angle Range

-20.0 deg ~ +20.0 deg (RES: 0.5 deg)

-

Max Response Speed

ca. 5ms

-

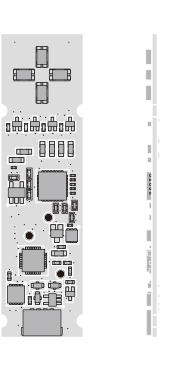

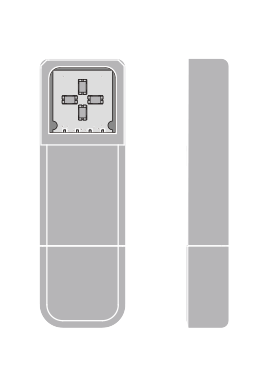

Sensor Part Size

55 mm (L) × 15 mm (W) × 2.5 mm (D)

-

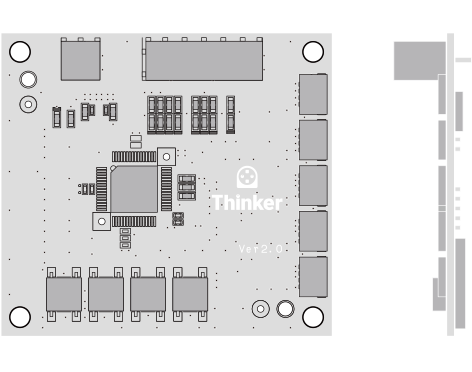

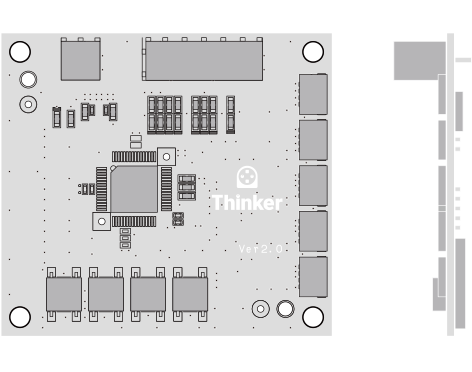

AI Board Size

55 mm (L) × 60 mm (W) × 14 mm (D)

-

Sensor Part Weight

ca. 3 g

-

Ambient Temp.

0 ~ 40 ℃ (no condensation)

-

Source Voltage

5 V

-

Waterproofing / Dustproofing

-

-

Dimensions (Unit: mm)

-

Measured Data

Distance, pitch and Yaw angle

-

Detection Range

1.5 ~ 20.0 mm (RES: 0.1 mm)

-

Angle Range

-20.0 deg ~ +20.0 deg (RES: 0.5 deg)

-

Max Response Speed

ca. 5ms

-

Sensor Part Size

69 mm (L) × 22 mm (W) × 11 mm (D)

-

AI Board Size

55 mm (L) × 60 mm (W) × 14 mm (D)

-

Sensor Part Weight

ca. 35 g (including 1 m cable)

-

Ambient Temp.

0 ~ 40 ℃ (no condensation)

-

Source Voltage

5 V

-

Waterproofing / Dustproofing

IP65 (Planned)

-

Dimensions (Unit: mm)

* See the catalogue for the Transmission Method.

*Specifications may change without notice.

FAQs

- What is the difference between TK-01N and TK-01G (under development)?

- TK-01G is placed in a protective case to protect the sensor board from water or getting dirty. TK-01N is designed for its sensor board to be used without a protective case in an environment where foreign matters do not adhere to infrared modules.

- I’d like to know the operating principles.

- Four infrared modules and Edge AI estimate the distance and angle of objects. Click here for details.

- I’d like to know the accuracy of the sensor.

- Resolution is 0.1㎜ for distance and 0.5 degree for angle.

- I’d like to know how to install the product to the hand.

- TK-01G: Fix the hand by inserting screws into the holes on the back of the sensor.

M3 screw × 4 places. Confirm the screw positions from the dimensions described in the catalogue.

TK-01N: Fix the hand with screws using the semi-circular notches set on the edge of the sensor board.

M2 screw × 4 places. Confirm the screw positions from the dimensions described in the catalogue.

For catalogues, contact us from here. - I’d like to know how to protect the sensor surface.

- When installing, ensure level difference from the surface for gripping a workpiece of the hand so that a workpiece does not contact the sensor surface.

- Are settings, etc. required after purchase?

- Almost no setting by you is required since the product has been factory-calibrated for various color of workpieces.

However, the measurement of transparent workpieces requires settings to increase light intensity of the sensor. - Are detectable workpieces limited?

- The product uses an infrared photoreflector, and detection is not ensured without sufficient light reflection to the reception unit of the sensor.

For example, in some cases, black glossless workpieces and sponge with fine asperities cannot be detected.

In addition, detection of objects thinner than the spot diameter may be difficult.

For details, contact us from here. - I’d like to know about the spot diameter.

- The product uses a diffuse reflectance sensor, and the spot diameter gets wider with increasing distance from the workpiece. It is approx. 15 mm at close range.

- Even if the sensor gets dirty, is the measurement ensured?

- Detection is not ensured without sufficient light reflection to the reception unit of the sensor, so be careful about dirt on light emitting-receiving surface.

In many cases, measurement with TK-01 series is not ensured in an environment where a standard reflective photosensor is not operable. - I’d like to know the form of communication with robots.

- Refer to the System Configuration described in the catalogue.

For catalogues, contact us from here. - I’d like to know what power supply is required.

- Power supply of 5 V, 500 mA is required.

- Which type of robots can be used?

- Refer to the System Configuration described in the catalogue.

For catalogues, contact us from here.